Part 1: Market Size and Growth

Ecuador has seen a steady rise in the demand for high-quality glassware over the last decade. The local market is shifting from basic plastic containers to elegant glass cups and sustainable tableware. This change is driven by a growing middle class and a booming tourism sector that requires durable glassware for hotels and cafes.

The market size for glass products in Ecuador continues to expand as consumers focus more on health and environmental safety. Glass is preferred over plastic because it does not leach chemicals and is 100% recyclable. From small artisanal workshops to large industrial plants, the variety of glass products like juice glasses and beer mugs is wider than ever before.

Government trade policies and local investment in manufacturing hubs have helped stabilize the supply chain. Several industrial clusters near Quito and Guayaquil benefit from shared logistics and energy resources. Local production is supported by tax incentives aimed at reducing reliance on expensive finished imports from overseas markets.

Deep Dive: Understanding the Ecuadorian Glass Landscape

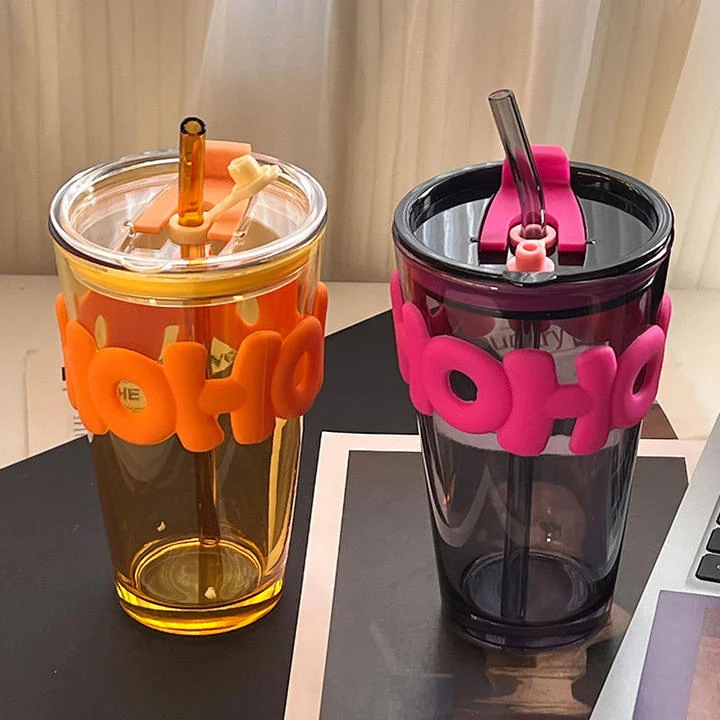

The glass industry in Ecuador is not just about making drinking vessels; it is about creating a functional art form that serves the hospitality industry. When we look at the numbers, the growth rate for domestic glass consumption has stayed around 4% annually. This is impressive considering the global economic fluctuations. The reason behind this steady climb is the diversification of product lines. Manufacturers are no longer just making simple water glasses. They are now producing specialized items like weighted whiskey glasses, delicate wine stems, and heat-resistant coffee cups.

One major factor influencing this market is the "Buy Local" movement. Ecuadorian businesses prefer sourcing from nearby factories to save on shipping costs and avoid the long lead times of international freight. This has forced local manufacturers to upgrade their machinery and adopt better quality control standards. In the past, high-end hotels would only buy European brands. Today, many of these establishments are proud to use locally made glassware that meets international safety and clarity standards.

| Factor | Impact Level | Description |

|---|---|---|

| Tourism Growth | High | Increases demand for hotel and restaurant glassware. |

| Sustainability | Medium | Drives consumers away from single-use plastics. |

| Logistics Costs | High | Encourages local sourcing over long-distance imports. |

| Design Innovation | Medium | Creates new niches for decorative and artisanal glass. |

The integration of modern technology into traditional glass blowing has also played a part. While large-scale automated lines handle the bulk orders for supermarkets, there is a thriving niche for hand-finished products. These premium items often find their way into gift shops and high-end boutiques. This dual-track development—mass production and artisanal quality—ensures that the industry can cater to every budget level within the country.

Part 2: Leading Companies

Cridesa (Cristalería del Ecuador S.A.)

Cridesa is one of the oldest and most respected names in the Ecuadorian glass industry. Based in Guayaquil, they have spent decades perfecting the art of mass-producing glass containers and tableware. Their facility is equipped with high-speed production lines that can churn out thousands of units every day. They started as a small factory but grew rapidly by securing contracts with major beverage brands and local retail chains.

Their product range is quite extensive, covering everything from standard water tumblers to specialized food jars. They focus on durability and clarity, ensuring that their glass does not cloud over time even with heavy use in commercial dishwashers. Most of their business comes from supplying the food and beverage industry, but they also have a significant presence in the home goods sector. Their items are found in almost every household in Ecuador.

The company is known for its commitment to efficiency and waste reduction. They use a high percentage of recycled glass cullet in their melting process, which helps keep costs down and protects the environment. Cridesa holds several ISO certifications for quality management, making them a reliable partner for both local and international buyers. They continue to innovate by exploring new glass compositions that are lighter yet stronger than traditional materials.

OI-Cridesa

This company represents a powerful partnership between local expertise and global industry leadership. By combining Ecuadorian market knowledge with international technical standards, they have set a high bar for glass manufacturing in the region. They operate out of strategic locations that allow for easy distribution across the country and into neighboring Andean markets. Their focus is heavily weighted toward high-volume industrial supply.

They specialize in glass packaging and tablewares that require precise specifications and high thermal resistance. Their production process involves rigorous testing to ensure that every glass cup or bottle can withstand the rigors of high-pressure filling lines and transport. This makes them a top choice for large-scale drink manufacturers and international distributors who cannot afford product failure.

The innovation at OI-Cridesa is driven by a global research and development network. They are often the first to introduce new design trends and lightweight glass technology to the Ecuadorian market. Their honors include multiple industry awards for sustainable manufacturing and safety. By maintaining a world-class production standard, they have successfully positioned Ecuador as a key player in the regional glass export trade.

Ferrum

Ferrum has carved out a unique space in the market by focusing on the intersection of household utility and modern design. Unlike the heavy industrial players, Ferrum often caters to the retail consumer who wants something stylish yet affordable. They have built a strong brand identity in Ecuador, synonymous with reliable kitchenware. Their history is rooted in providing functional solutions for everyday living.

Their product line includes a variety of glass cups, mugs, and storage containers. They are particularly well-known for their sets of drinking glasses that feature contemporary patterns and ergonomic shapes. They also produce glass bowls and plates, allowing them to offer complete table settings. Their service model focuses on the retail market, working closely with department stores and home improvement centers.

One of their key strengths is their ability to adapt to changing consumer tastes quickly. They frequently update their catalog with new shapes and sizes to match global trends in home decor. Ferrum emphasizes safety and non-toxic materials, which is a major selling point for families. They have received recognition for their business growth and their contribution to the local manufacturing economy over the years.

| Company | Founded | Core Products | Industries | Certifications |

|---|---|---|---|---|

| Cridesa | 1960s | Tumblers, Jars | Retail, F&B | ISO 9001 |

| OI-Cridesa | 1990s* | Packaging, Glassware | Industrial, Export | FSSC 22000 |

| Ferrum | 1970s | Tableware, Mugs | Home Goods, Retail | INEN Standards |

Part 3: Trade Shows and Industry Events

Ecuador hosts several trade fairs that are essential for anyone in the glassware and hospitality business. The Expo Horeca is perhaps the most significant event for those looking to see glass cups in action. It brings together suppliers, manufacturers, and buyers from the hotel, restaurant, and cafe sectors. It is a great place to see the latest designs in barware and dining sets.

The event usually takes place in Quito or Guayaquil and attracts thousands of visitors over three days. For glass manufacturers, this is the primary stage to showcase new product launches and custom branding capabilities. It provides a direct link between the factory and the end-user, allowing for immediate feedback on glass quality and design. Many long-term supply contracts are signed during this busy week.

Another important event is the Feria Internacional del Hogar, which focuses more on retail and consumer goods. This show is ideal for discovering glass products designed for the home, such as decorative pitchers and everyday drinking sets. It is a vibrant event where manufacturers can test new concepts with the general public. The atmosphere is energetic, with cooking demonstrations and table-setting competitions highlighting the versatility of glass.

| Event | Date | Location | Highlights |

|---|---|---|---|

| Expo Horeca | Annually (Sept) | Quito/Guayaquil | Focus on hospitality and commercial glass. |

| Feria del Hogar | Bi-annually | Guayaquil | Retail trends and household glassware. |

Part 4: Impact of Global Trade Policies

Global trade policies have a direct impact on how glass is produced and sold in Ecuador. Because the country uses the US Dollar, it is sensitive to price changes in raw materials and energy on the international market. Trade agreements with neighboring countries in the Andean Community allow for easier export of Ecuadorian glass, but they also bring in competition from Colombian and Peruvian factories.

The push for "Import Substitution" has been a major theme in recent years. The government has implemented tariffs on certain finished glass imports to encourage businesses to buy from local manufacturers like Cridesa. This has helped the domestic industry grow, but it also means local factories must keep their technology up to date to satisfy the quality demands of international brands operating in Ecuador.

Supply chain risks are a constant concern for glass makers. While Ecuador has sand and other raw materials, certain specialized chemicals and high-tech machinery must be imported. Any disruption in global shipping or changes in maritime law can lead to delays in production. To combat this, many manufacturers are keeping larger inventories of spare parts and looking for regional suppliers of raw ingredients to ensure a steady workflow.

Part 5: Conclusion

The glass cup manufacturing industry in Ecuador is in a strong position for future growth. The combination of a rising tourism sector and a shift toward sustainable packaging creates many opportunities for local factories. Businesses that can offer customized designs and eco-friendly solutions will likely see the most success. As long as the local demand for quality dining experiences continues to climb, the future of Ecuadorian glass looks very bright.

However, there are still challenges that cannot be ignored. Rising energy costs can make the glass melting process very expensive, which might lead to higher prices for the end consumer. Manufacturers also face stiff competition from low-cost imports and alternative materials like treated ceramics. To stay ahead, Ecuadorian companies must continue to invest in automation and unique branding to prove that their products offer the best value for money in the long run.